Scarborough Subway Extension machine prepares to dig tunnel

Metrolinx marks milestone for Scarborough Subway Extension as TBM gets lowered into launch shaft.

May 2, 2022

After a journey across the Atlantic Ocean, Diggy Scardust, Scarborough’s aptly named tunnel boring machine (TBM), is assembled and getting ready to start its tunnelling journey at Sheppard Avenue and McCowan Road.

Crews on site have completed building the approximately 28-metre-deep shaft and parts of the TBM are now being lowered into the shaft.

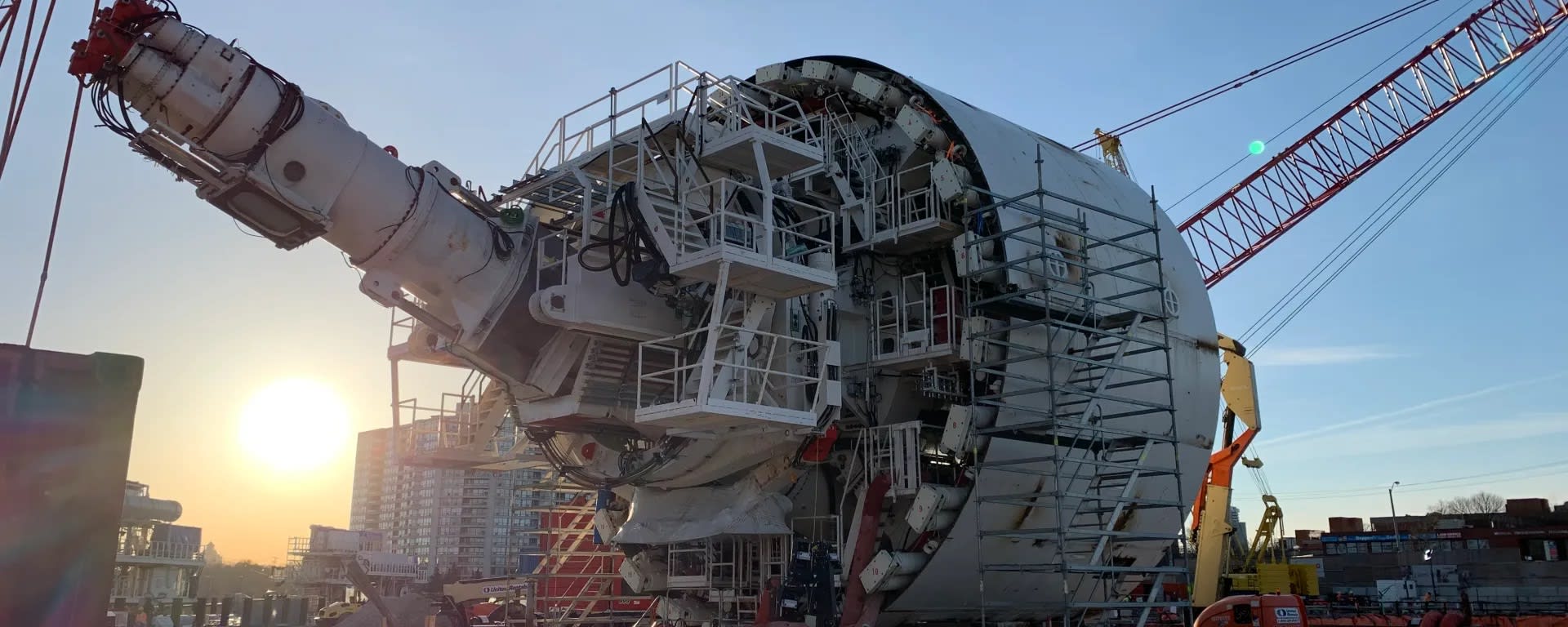

The main shield of Diggy Scardust, assembled and being prepared to be lowered into the launch shaft. (Metrolinx photo)

This is being done by using a special crane, called a gantry crane, that lifts and then carefully lowers very heavy equipment. All assembled, Diggy Scardust weighs 2,050 tonnes – roughly the weight of 42 GO train cars.

The gantry crane system being used to lower the TBM. (Metrolinx photo)

The TBM is being lowered in massive pieces.

The machine’s main shield houses the majority of the operational systems of the TBM, such as the main drive system used to rotate the cutterhead and the thrust jacks used to advance the massive TBM. It also features the screw conveyor which is used to remove excavated material from the cutterhead chamber, and the segment erector used to install the tunnel liners.

A close-up shot of the tunnel boring machine with it’s catchy nametag. (Metrolinx photo)

The main shield was the first piece to be lowered and will be followed by the tail can and then the cutterhead. All these pieces, once assembled, will form the biggest tunnel boring machine used for a transit project in Canada to date.

Lowering each piece is a long process that takes hours and includes a lot of coordination from the crew on site.

After all the pieces are lowered, crews will connect them together in the launch shaft and get the TBM ready to start its 7.8-kilometre tunnelling journey.

Bird’s eye view of the launch shaft site with the main drive of the TBM lowered into the launch shaft. (Metrolinx photo)

When tunnelling begins, Diggy Scardust will travel south, going about 10 metres a day, towards Midland Avenue and Eglinton Avenue, where crews will eventually lift it out of the ground.

As it digs through the earth, soil and rocks will be removed by a screw conveyor and transported back to the launch shaft site using a belt conveyor. They will then be hauled off-site for proper disposal.

The TBM gantry system that will be lowered and connected to the TBM. The gantry contains support systems for the TBM and a belt conveyor to move excavated material to the continuous belt conveyor up to the surface. (Metrolinx photo)

Some quick facts about the TBM:

- With a bore diameter of 11.9 metres, Diggy Scardust is taller than two giraffes

- At 84 metres in length, Diggy is about the same length as three GO Train cars

- Diggy will install a 10.7-metre diameter single subway tunnel which will accommodate trains travelling in both directions – the first of its kind in Toronto

What’s next?

As crews continue to prepare Diggy for tunnelling, they are already turning their attention to other parts of the project route.

Headwall construction is underway for the emergency exit and station buildings. This work needs to be completed before the TBM arrives underground at each location.

For the latest information on the Scarborough Subway Extension, visit the project website and follow the project on Twitter @ScarbSubwayEXT.

by Joshua Patel Metrolinx communications senior advisor, subway program